Date – 03/03/2011

Clinical application of sandblasting using the MiniblasterTM from Deldent Ltd

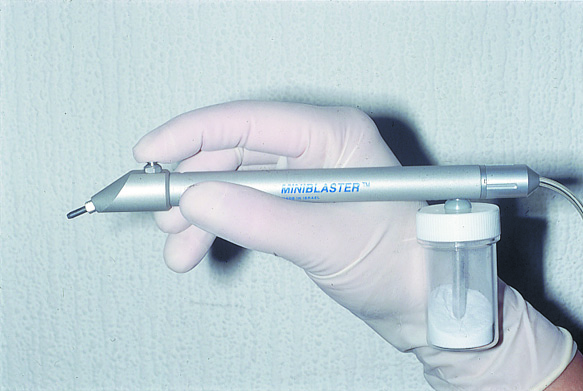

Suitable for intraoral use, the MiniblasterTM is designers to enhance adhesive dentistry procedures.

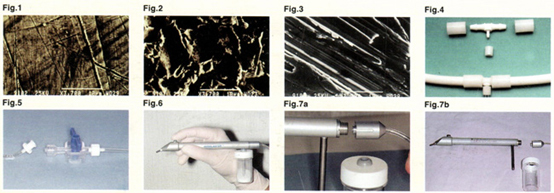

Use of the MiniblasterTM is said to significantly increase the micro – retention of bonding surfaces. The increase in surface microroughness that can be achieved by sandblasting can be seen in 3,700 XSEM micrographs. Figure 1 shows polished gold, and Figure 2 shows the surface after sandblasting. The resulting retention significantly is greater than that achieved by the grooves produced by roughening with a bur (Figure 3).

The MiniblasterTM can be installed with the installation kit supplied with the unit (figure4). For maximum efficiency, the unit should be operated at 80-100 psi. An in- line, high-pressure stopcock is provided to permit the sandblaster to be readily disconnected from its air supply line after installation (Figure 5), facilitating transport from one operatory to another. Additional installation kits are available.

The index-finger-operated control valve on the top of the unit (Figure 6) is ergonomically designed and positioned. The control button makes the sandblaster equally simple to operate by either right or left-handed operators.

The entire unit is autoclavable. Following disconnection of the rear connector and removal of the powder chamber (Figure 7a), all components can be prepared for sterilization packaging in the usual manner (Figure 7b).

The spray head rotates via a unique ratchet system for optimal directional control (Figure 8).

A tungsten carbide extension spray nozzle with 360° that screws over the standard nozzle is available (Figure 9). This extension nozzle is rarely needed, but can offer access to areas not easily reached by the standard nozzle.

The MiniblasterTM can be used for surface preparation prior to bonding to all dental materials including : Precious, semiprecious, and nonprecious metals; porcelain; composite; and resin materials. In principle macro retention such as under-cuts should be employed where possible in conjunction with the micro retention produced by the MiniblasterTM . Although 50-micron aluminum oxide is abrasive of choice for routine use, 90-micron can be employed for more aggressive work and cement removal. Figure 10a-d shows the intraoral repair of a fractured porcelain facing. Pre-op conditions are illustrated in figure 10a, sandblasting in Figure 10b, and bonding application in Figure10c. An opaquing material should be applied to mask any exposed metal. Cotton rolls or a rubber dam should be used for area isolation. Figure 10d shows the repair 12 months later.

Figure 11a and 11b shows removal of cement from a crown prior to recementation.

Sandblasting of orthodontic bands is said to significantly improve their retention (Figure 12).

Sandblasting of detached orthodontic brackets will remove composite and allow rebonding. The stages in preparation of a simple orthodontic lingual retainer are: Wire adaptation (Figure 13a) followed by sandblasting (Figure 13b). The bonded retainer is shown in Figure 13c.

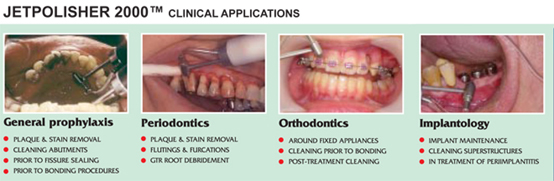

But before they can enjoy the whiter, brighter, more beautiful smiles they demand, there’s a prerequisite: a clean tooth surface, free of bacterial plaque and stains.

Traditionally, a rubber cup and fluoridated prophy paste method has been used for plaque and stain removal. However, this technique has obvious limitations in areas of crowding, around orthodontic fixed appliance and of course, in areas of limited access such as under and around fixed multiple unit restorations.

Early Years of Air Polishing

Air polishing was developed in the early 1970s as a technique for fast and efficient removal of extrinsic stains, plaque and other soft deposits from the teeth. It was designed to replace the prophy cup method and has been shown to save more than 50% of the clinical time spent on this tedious procedure. The technique was widely acclaimed when introduced, but this initial enthusiasm was somewhat tempered when it was found that the early technology resulted in frequent clogging problems with the system and the need for frequent servicing and maintenance.

Air polishing units typically generate a stream of pressurized air, carrying specially graded particles of a mild soluble abrasive, such as sodium bicarbonate. The abrasive is directed, in the presence of a stream of water, at a tooth surface to be cleaned. The mixture of water and powderladed stream occurs on the tooth surface and forms a “slurry” that is responsible for the cleaning action.

Drawbacks of Conventional Units

In most currently available units, the water stream emits through a separate nozzle that may be concentric to that of the powderladen air stream nozzle. The resulting buildup of crystalline anhydrous sodium bicarbonate deposits in the lumen of the air/powder nozzle results in clogging. Several attempts have been made to overcome this, including the introduction of a ‘bleed air stream’ that flowed constantly through the air/powder nozzle and changes in the chemical composition or physical nature of the powder

More recent technology produces a slurry by introducing the water stream into the powder-laden air stream, within the spray head at a critical moment, to produce a fully homogeneous stream that is emitted from a single nozzle. This stream technology configuration has not only been shown to prevent nozzle clogging by preventing the buildup of deposits, but also results in a much more efficient cleaning action because the slurry is formed prior to emission. Air polishing devices were originally designed to be standalone tabletop units. They have been considered to be the equipment of choice for the hygiene department, sometimes being combined with ultrasonic scaling devices. They offer a large powder chamber holding enough powder for multiple treatments, along with the convenience of a lightweight, fully autoclavable handpiece design. They are activated by a dedicated foot control that can select either a polishing or rinse mode and they require connections to water, air and electrical outlets. As such, they are normally allocated to a particular treatment room.

Air Polishing Advantages

There is increasing awareness among clinicians —periodontists, orthodontists, prosthodontists and restorative dentists alike—that having a simple, easily transportable air polishing unit can reduce the tedium of stain and plaque removal for many procedures. For example:

Pencil Type Units –- A Step In The Right Direction

Some current handheld air polishing devices connect directly to your dental unit’s handpiece tubing. Activation of the unit’s foot control generates the water and air supplies for the device. These “pencil-type” devices are of limited use in a busy hygiene office, but can be easily transported between operatories, conveniently stored, and can be ready for action on short notice. Because they have integral powder reservoirs with limited powder capacity, they are mostly not fully autoclavable, and the drag of the powder reservoir makes long-term use inconvenient and tiring. In addition, there is considerable inconvenience associated with having to constantly refill the powder reservoir.

Deldent’s New Generation – The Ultimate Solution

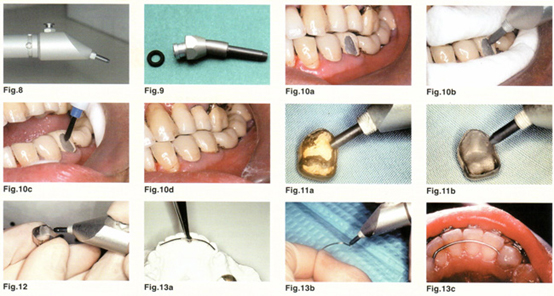

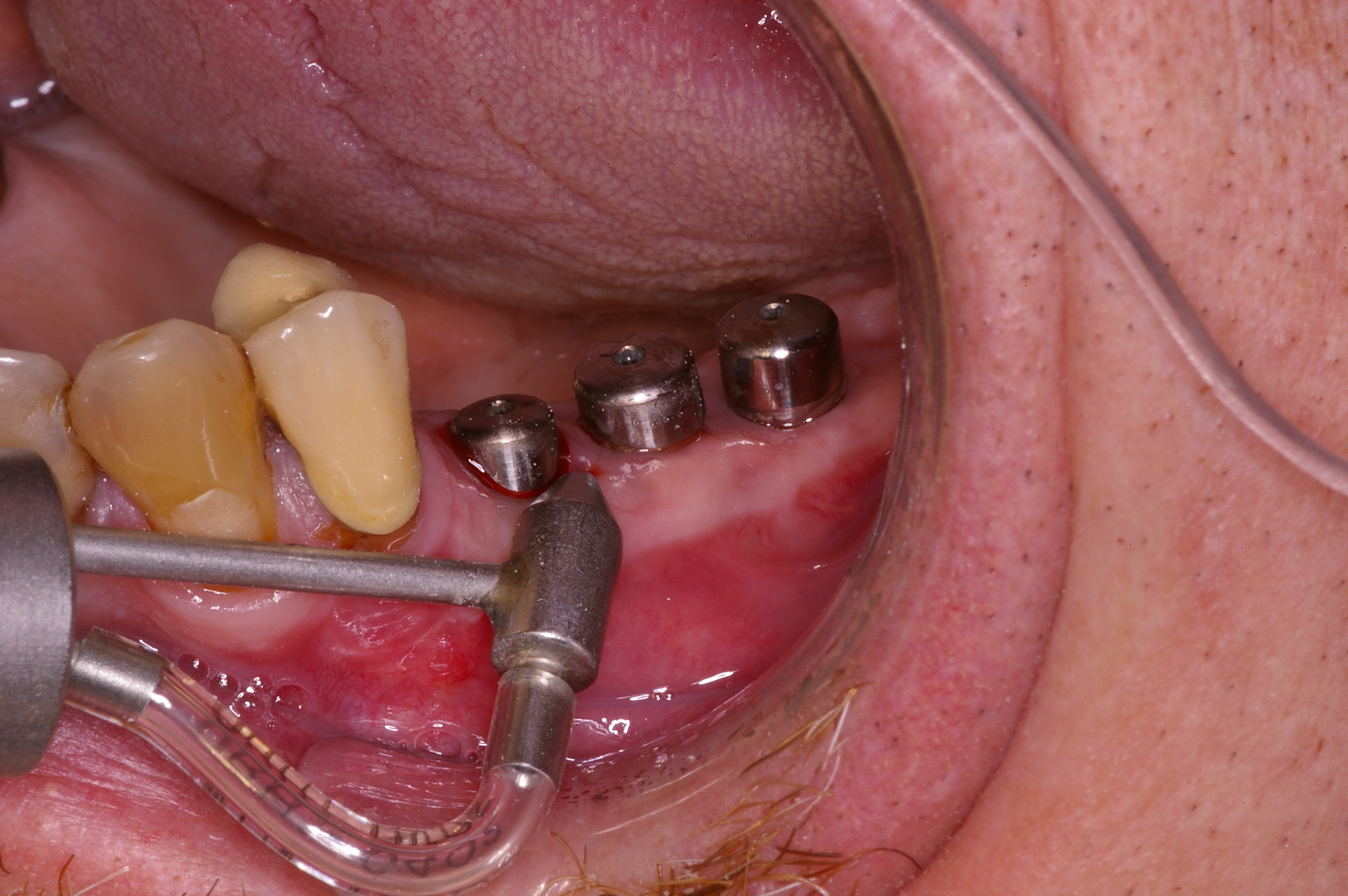

Deldent air polishers incorporate Homogeneous Stream Technology (H.S.T.®) that eliminates nozzle clogging. These devices have been cleared by the FDA for cleaning around titanium implants. The H.S.T. slurry begins to soften the powder particles before they impact the implant surface, and independent research has shown this system causes no damage to titanium implant and transmucosal elements. While still retaining the convenience and portability of connecting directly to the dental unit’s handpiece tubing, these devices are designed so that the powder reservoir with a capacity for multiple prophy treatments is separate from the fully autoclavable handpiece. This eliminates the drag associated with handheld units. The new H.S.T.- equipped units are compact, taking up minimal workspace. They can also be quickly disconnected for storage or for transportation from one workstation to another. They incorporate the advantages of the standalone tabletop units, offering both rinse and polishing modes, without the disadvantages. These units are suitable for the busy hygiene practice but are alsoideal for the doctor. With a new generation H.S.T. air polisher, you can enhance clinical procedures and increase patient satisfaction.

Deldent’s airpolishers have been cleared by the FDA for cleaning around titanium implants.

The JetPolisher 2000-Every Clinician Should Know

Ann M. Drewenski, RDH

A Registered Dental Hygienist (RDH) has the responsibility to their patients to help them maintain great oral health and entire body health. This is accomplished by the elimination of plaque and biofilms. Researchers have found evidence that the amount of bacteria in subgingival plaques, the deep plaques in periodontal pockets and around the teeth, may contribute to an individual’s risk of a heart (disease and other systemic conditions such as Diabetes, Respiratory Disease and Pregnancy) attack, according to studies appearing the Journal of Periodontology. (The same bacteria have also been associated with Diabetes, Respiratory Disease and Pregnancy). While Every patient is different and may present with many different situations, whether they have implants, full orthodontic brackets, periodontal patient or a routine general prophylaxis, they all (still) accumulate and develop plaque. There are many different instruments and units available to remove these harmful bacteria. The focus of this article will be on who can use the JetPolisher 2000®, what the JetPolisher 2000 accomplishes, how the JetPolisher works, and the many advantages of the JetPolisher 2000.

I think a description of what a Jetpolisher2000 is, should precede who uses it – ALAN The Jetpolisher 2000 is a small, compact air/powder polishing system that is easily portable from unit to unit.

It requires no installation, and connects directly to the 4-hole handpiece tubing connector of the dental unit. Pressure on the regular foot control of the dental unit then activates the Jetpolisher 2000 The Jetpolisher 2000 has a unique patented homogenous stream technology H.S.T. polishing system, which delivers a gentle thorough cleaning in less time than other methods.

More than 50% in time can be saved, and the procedure is less tedious for the clinician than other methods, such as the prophy cup and paste. The H.S.T. system works by the air, water and powder are mixed homogeneously prior to emission from the nozzle producing a more efficient polishing stream, which creates only 35 p.s.i amount of air pressure, providing a gentler and safer procedure.

The H.S.T.system has been shown to cause no damage to titanium implant surfaces (Barnes et al, I.J.O.M.I. 1991). This system also eliminates the clogging that’s so frustrating with other polishers.

The nozzle clogging is eliminated by preventing the build up of anhydrous sodium bicarbonate that occurs at the nozzle orifice in other systems. A Registered Dental Hygienist can (has the ability to) use the JetPolisher2000 after scaling, to remove (removing) stain and plaque during a routine prophylaxis.

The efficient homogenous stream generated by the Jetpolisher 2000 easily reaches interproximal areas where crowding exists, as well as under and around even complex restorations. (This is an airpolishing system which is a technique for cleaning tooth surfaces, and efficiently removing stain and soft tissue deposits.)

The JetPolisher 2000 is superb for cleaning abutments, prior to cementation of restorations, removal of fissure plaque prior to fissure sealants, and to clean enamel prior to bonding procedures.

The sodium bicarbonate stream is completely soluble and so there are no insoluble deposits left on the tooth surface after rinsing to interfere with bonding procedures.

The JetPolisher 2000 works great prior to whitening procedures. It is also ideal for cleaning around fixed appliances i.e., orthodontics, where rotary instruments cannot reach. It is the only unit that is FDA cleared for cleaning around implants during implant maintenance procedures, (cleaning superstructures, and in treatment of peri-implantitis) it is not FDA cleared for these procedures, so please remove this sentence!

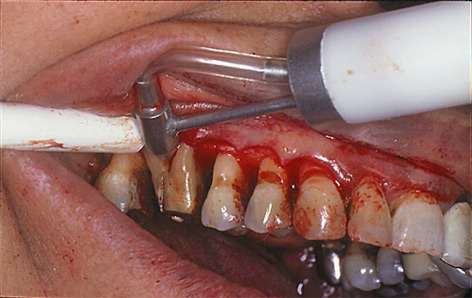

2. The JetPolisher 2000 is a great tool that can be utilized by Periodontists during periodontal treatments – for cleaning root irregularities and depressions. (and also for guided tissue regeneration, which requires root debridement to achieve biocompatible surfaces for regeneration of lost supporting tissues).

-If you have seen it used during regenerative procedeures in the clinics you work then you can mention this as a personal note, but if not, it is not safe to make this claim!!

The FDA might object!!! (The JetPolisher 2000 reaches inaccessible areas such as interproximally, its, fissures, grooves and around orthodontic fixed appliances).

Already mentioned above! In summary The (many features of the) JetPolisher 2000 offers many excellent features and benefits. (are the unit has). The unique patented HST system, is a single nozzle system producing a low pressure stream with softened particles, that will not damage titanium implant or transmucosal element surfaces. It is small and compact, and is FDA cleared for cleaning around titanium implants.

The patented self cleaning head eliminates nozzle clog that is a major cause of down time with other systems. It has a fully detachable and autoclavable handpiece, and the unit is fully portable, requires no installation, and has a large volume powder reservoir sufficient for multiple prophys. The JetPolisher 2000 is a fantastic system for the clinician to utilize on their patients to help maintain a healthy environment orally and systemically.